Running at optimal efficiency is a requirement for any fleet’s success — a company’s competitiveness relies on its drivers’ ability to get to their destinations quickly. That’s why when vehicles don’t run, it can be a significant problem. Vehicle downtime reduces the fleet’s efficiency and capability, resulting in losses in productivity and revenue. It can also incur unexpected repair and retrieval costs. In this article, we’ll discuss how to reduce downtime for your fleet to avoid these issues and keep your operations running smoothly.

When a vehicle in your fleet breaks down, it affects your business in several ways. Some negative effects of downtime on fleets include:

In total, downtime expenses can run eight times higher than anticipated, and each out-of-service vehicle costs fleets between $850 and $1,000 per day on average. This impact can be especially hard on smaller companies, which is why it’s essential for these businesses to know how to avoid downtime effectively.

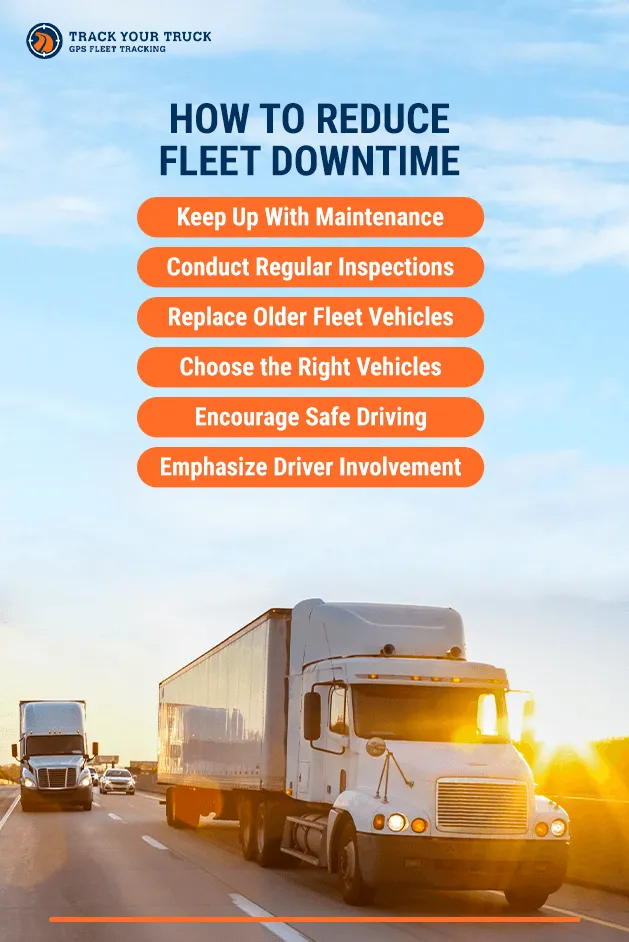

With the high costs and negative effects of downtime, fleets need to take steps to keep downtime to a minimum. While downtime may still occur, your company can be proactive about preventing it by implementing preventive measures and creating contingency plans. Some methods companies can use include the following:

One of the essential steps to avoiding fleet downtime is to perform regularly scheduled maintenance. Fleet maintenance costs are on the rise, with average expenses rising 50% between 2017 and 2018 alone. However, regular preventive maintenance can help avoid more expensive repairs down the road.

Preventive maintenance, also known as a PM program, establishes guidelines for when vehicles need to be serviced. This regular servicing allows maintenance crews to identify performance issues before they become problems, which reduces downtime potential. Additionally, this scheduled downtime for vehicle maintenance lets businesses prepare in advance and set repairs during off-hours or slow days. On average, vehicles involved in scheduled PM programs experience 20% fewer days of maintenance-related downtime than vehicles that aren’t.

In addition to keeping up with vehicle maintenance, companies should perform regular vehicle inspections. These inspections should be frequent and thorough, designed to identify potential issues before they knock a vehicle out of the fleet. If possible, install onboard telematics systems to collect data on fault codes and other alerts that may indicate a problem.

No matter your method, keep in close contact with the maintenance provider who is performing the inspections. Regularly check in with them so they understand your fleet’s needs and run inspections to meet your requirements.

After a certain mileage, fleet vehicles reach a point where they need more frequent and extensive maintenance. While mechanical breakdowns are much less common today than they were 20 years ago — and cars tend to last longer — vehicles still age to a point where replacement may be a necessity. While the cost of replacement is daunting, remember that this is significantly less than the long-term costs of keeping older vehicles.

Older vehicles need more maintenance and are more likely to fail on the road, resulting in unexpected downtime. Work within your company to determine when to retire vehicles, and be sure to account for replacement costs in your budget.

Always choose the right vehicles for your fleet and each individual job. When looking to purchase vehicles, select ones that are suitable for the types of jobs your business handles. Also, search for models with proven track records for low maintenance needs.

After you’ve purchased your vehicles, make sure to assign the right ones to individual jobs. Overloading vehicles results in greater wear and tear, increasing the potential for unplanned downtime. Vehicle overloading is the number one cause of unscheduled maintenance for trucks. Overloading can also reduce a truck’s emergency handling capability — such as braking speed and the distance required to brake — which can eventually cause an accident.

Accidents are a significant cause of unplanned downtime — on average, 20% of fleet downtime results from an accident. While some accidents are unavoidable since other drivers on the road may cause them, businesses can reduce downtime due to employee-caused accidents by managing their drivers’ driving behaviors.

Train drivers in safe driving tactics regularly and keep track of accident records to help identify trends. Another potential plan is to monitor driver behavior by using vehicle tracking so you can identify speeding, heavy braking, sharp turns, sudden stops and other concerning actions. You may also equip your trucks with speed-limiting devices to restrict maximum vehicle speeds to the legal limit.

Another common cause of downtime is driver error. Many drivers don’t pay attention to dashboard lights, and push their vehicles on instead of taking them to the garage. Drivers may also not refuel properly, driving for long periods with an empty reservoir and damaging internal systems. While vehicle monitoring systems can help avoid these problems by analyzing vehicle components, you should also stress the importance of maintenance to drivers and involve them in the upkeep process.

The most effective way to involve drivers is through training. While it may seem redundant, have all drivers undergo regular retraining regardless of their experience. This training should include an overview of safe driving practices and discuss the importance of proper refueling and timely maintenance. Training may also include basic vehicle inspection skills, such as how to identify bad tires, wheels or engine parts and what engine sounds may indicate a problem.

Equally important is providing a way for drivers to communicate concerns. Develop and communicate efficient methods for drivers to request maintenance when they notice changes in vehicle performance. Encouraging this behavior is a great way to identify unseen vehicle problems before they result in unexpected downtime.

Despite your best efforts to avoid it, fleet downtime can still happen. Unexpected breakdowns, accidents, human error and other events can still sideline vehicles even if you have a robust system to avoid these things. However, you can make the most of downtime when it happens. A few ways to keep downtime to a minimum and use it to your advantage include the following tips:

Using these methods, you can make the most of downtime if it happens and work to avoid it in the future. Even if you don’t think it will happen, it’s best to stay prepared for it if it ever does.

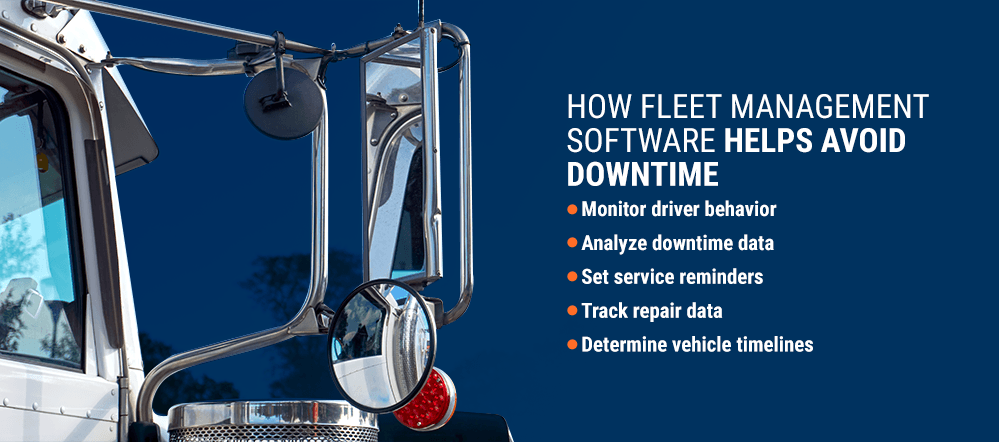

Ultimately, the best way to avoid downtime is to monitor your vehicles, drivers and maintenance schedules regularly. Implementing thorough maintenance programs and training schedules can do wonders to avoid downtime, but you can further improve your vehicle uptime by combining your human resources with technology assets. One of the best technologies available to help with managing fleet downtime is fleet management software.

Efficient GPS fleet management software collects information about each vehicle and driver and relays that data to a central database. This system gathers all relevant fleet data and can assist you in preventing downtime in the following ways:

Using these functions and more, fleet managers can gain greater control and insight into each vehicle and their business at large, allowing them to make informed decisions regarding fleet management downtime.

Fleet downtime is a significant problem for many companies. However, with quality fleet management software, you can gain the information and insight you need to create detailed preventive maintenance schedules, tailor training programs and make successful vehicle purchasing decisions. If you’re looking for quality fleet management software to help your company avoid downtime, Track Your Truck is here to help.

Track Your Truck provides companies with advanced GPS fleet tracking solutions that utilize the latest in tracking technology. Our smart tracking technology and easy-to-use desktop and mobile apps collect and communicate thorough data on each vehicle in your fleet, allowing you to gain meaningful insights that can help you avoid downtime and maximize fleet efficiency.

Our advanced technology is highly customizable to meet your business’s unique needs, and we offer flexible service agreements to ensure customer satisfaction. On top of it all, we offer U.S.-based support provided by a dedicated and helpful team and backed by numerous “how-to” videos to help you make the most of our service.

Track Your Truck can help your business maximize productivity, streamline operations, reduce overhead costs and avoid downtime with our comprehensive service. Learn more about what we can offer you by browsing our blog, or request a quote today!